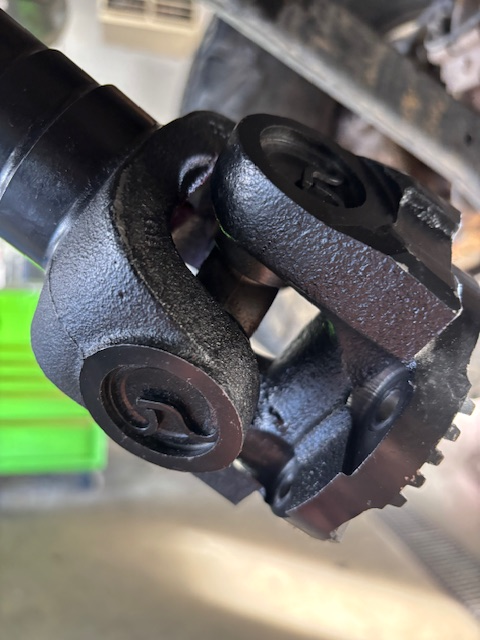

Double Cardan Joint Failure: What It Is and What It Can Damage

If you drive a 4x4 or a vehicle with a lifted suspension, chances are your driveline uses a double cardan joint—a heavy-duty version of a universal joint (U-joint) designed to reduce vibration and handle steep driveline angles. While these joints are durable, they’re not indestructible, This week we had a 2009 Dodge Ram and this customer find out just how much can be damaged when this joint fails. When a double cardan joint fails, it can cause serious drivability issues and even damage major surrounding components.

Here’s a breakdown of what the double cardan joint does, how it fails, and the parts that can be affected when it does.

What Is a Double Cardan Joint?

A double cardan joint, sometimes called a CV-style U-joint, uses two U-joints and a centering mechanism to keep the driveline operating smoothly under changing angles. It’s commonly found in:

- 4x4 trucks and SUVs

- Lifted vehicles

- Vehicles with front driveshafts running at steep angles

Its job is to reduce vibration and keep power smoothly transferring from the transmission or transfer case to the differential.

Common Causes of Double Cardan Joint Failure

A double cardan joint can fail for several reasons, including:

- Lack of lubrication

- Wear in the U-joints

- Broken or worn centering ball (also called the centering yoke or ball stud)

- Corrosion or contamination

- Excessive driveline angles (often caused by suspension lifts)

- Old age and high mileage

Once wear starts in one part of the joint, it quickly spreads to the rest of the assembly.

Symptoms of a Failing Double Cardan Joint

Drivers often notice:

- Vibrations at certain speeds or under load

- Clunking during acceleration or deceleration

- Chirping or squeaking sounds

- A noticeable shake at higher speeds

- Difficulty maintaining smooth 4WD operation

Ignoring the early signs can lead to a complete failure.

Major Parts That Can Be Damaged During Double Cardan Joint Failure

When the double cardan joint fails, it doesn't just stop working—it can take other components down with it.

1. U-Joints

U-joints are the first components to wear out. Once loose or seized, they create vibration and additional stress on the centering mechanism.

2. Centering Ball and Spring Assembly

This is the heart of the double cardan system.

When the centering ball wears out or breaks:

- The two U-joints lose synchronization

- The driveline can wobble

- Vibrations rapidly increase

- Further damage spreads to the entire joint

A failed centering ball almost always requires rebuilding or replacing the double cardan assembly.

3. Yokes (Drive Yoke or CV Yoke)

When the joint becomes loose, the yokes can elongate, crack, or wear unevenly.

If the yoke becomes damaged:

- It may not hold a new U-joint securely

- The driveshaft may require full replacement

4. Driveshaft Tube

A violently shaking double cardan joint can:

- Bend the driveshaft

- Throw it out of balance

- Crack the weld seams

A bent driveshaft usually means replacement, not repair.

5. Transfer Case Output Shaft

One of the most expensive failures.

If the joint fails catastrophically, the driveshaft can slam around under the vehicle and damage:

- The output shaft

- The housing

- Seals and bearings

A damaged output shaft may require transfer case teardown or replacement.

6. Exhaust System

A flailing driveshaft can strike the exhaust, causing:

- Dented or crushed pipes

- Broken O₂ sensors

- Rattling heat shields

7. Floor Pan and Underbody Components

In severe cases, a separated driveshaft can:

- Punch dents into the floor pan

- Damage brake lines

- Tear wiring harnesses

- Bend crossmembers

How to Prevent Double Cardan Joint Failure

- Grease U-joints regularly (if serviceable)

- Address vibrations early

- Inspect joints after off-road use

- Use proper driveline angles with suspension lifts

- Replace worn components before they fail completely

Routine inspection is the best way to catch problems before they cause major damage.

Final Thoughts

A double cardan joint is a strong and reliable part of your vehicle’s driveline, but once it starts to fail, it can quickly cascade into much larger problems. Staying ahead of wear and listening to early symptoms can save you from expensive repairs to your driveshaft, yokes, or even your transfer case.

If you’re experiencing vibration, clunking, or strange driveline noises, it’s worth having a professional inspect the double cardan assembly before the failure spreads.